At Associated Manufacturing, we offer our clients the complete design to delivery solution. Our design and tooling section helps our clients in each phase of the production and new product development, right from design improvements to quality improvements resulting in cost competitiveness and shorter time to market.

Our manufacturing facility is well designed in our 100,000 Sq. Ft. Plant area equipped with latest machines. The equipment’s compliments our front end designing and tooling capabilities providing a precision based defects products. Our flexible production model allows us to handle low volume and high volume production of mix products equally efficiently.

To know more about our services.

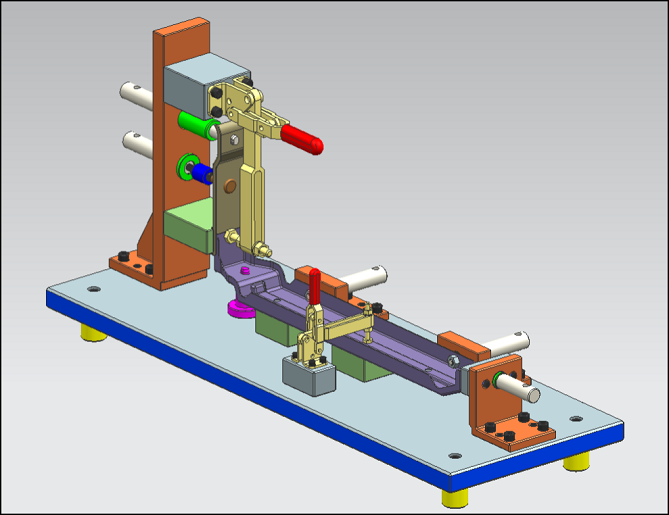

Contact usThe design team has an average experience of 20 years in designing and building tools that optimize manufacturing processes. Our turnaround time on new projects and designs is relatively short. Our designers and our tool makers use concurrent engineering techniques to achieve optimum quality, cost and productivity.

Our Tool manufacturing facility is integrated with our other manufacturing facility under the same roof. The Tool manufacturing facility is spread over 5,000 square foot having a mix of CNC and VMC machines supplemented by conventional machines. We aso have access to more capacity if needed.

We have additionally developed core competency for manufacturing of precision deep draw and forming tools.

Our designing and manufacturing software includes:

- Siemens NX

- Siemens Solid Edge

- HyperForm

- AutoCAD®

Every aspect of our facility reflects our dedication to quality, precision and efficiency.

Specialized Manufacturing Capability

Along with our expertise on various products and processes in sheet metal, Associated Manufacturing also has capabilities in designing and producing Single “V” Groove, Poly Groove and Split Pulleys from 50 mm to 350 mm diameter. These are made out of Sheet Metal as opposed to Pulleys made from Cast Iron process.

Advantages of Sheet Metal Pulleys over Cast Iron Pulleys

- Weight reduction

- Increased belt life

- Superior heat dissipation

- Noise reduction

The system is monitored with trend analysis, internal audits, frequent customer audits and surveillance audits by the Registrar.

We encourage employee participation, on-going training and monitoring of training effectiveness.Some of our Customers have qualified us with compliance to the popular German automotive standard VDA 6.3.

Take the next steps.

Explore More

Facility Tour

Take a tour of our facility and understand how we bring our promises to life.

Our Projects

We have delivered over 1,000 products till date. Check out a few of our notable projects.